Central to the safe operation of a lift truck is understanding the factors that affect stability. When it comes to  telehandlers, many of these factors come into play, but there are a few more to consider that are specific to telehandler stability.

telehandlers, many of these factors come into play, but there are a few more to consider that are specific to telehandler stability.

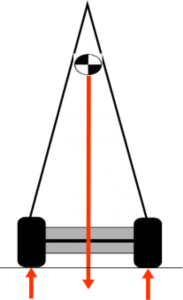

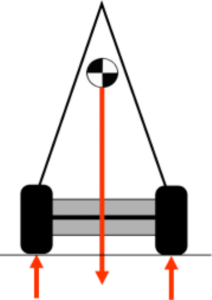

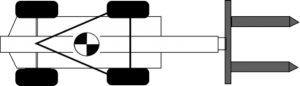

Start with the fact that a telehandler’s stability triangle and pyramid have a larger base due to a wider and longer chassis (and often the presence of outriggers). On some models outriggers can increase the lifting capacity (at maximum horizontal outreach) by as much as six times.

Secondly, telehandlers stability relies on this wider base so that they can reach higher than

forklifts. But keep in mind that the higher the lift, the closer the center of gravity comes to the edge of the pyramid. If it reaches the edge, the result will be a tip over.

forklifts. But keep in mind that the higher the lift, the closer the center of gravity comes to the edge of the pyramid. If it reaches the edge, the result will be a tip over.

Third, the counterweight on a forklift is static whereas on a telehandler it is dynamic. Part of this is due to the fact that the boom (which is part of the  counterweight) is usually attached behind the operator’s cab. This means that when the boom is elevated, the center of gravity shifts toward the rear of the stability triangle which is narrower. Add in a slope or turning and you have created a very dangerous situation.

counterweight) is usually attached behind the operator’s cab. This means that when the boom is elevated, the center of gravity shifts toward the rear of the stability triangle which is narrower. Add in a slope or turning and you have created a very dangerous situation.

The last item to consider is the environment. Telehandlers typically operate on rough surfaces that may have pits and voids. In addition wind can have an effect. A suspended load might start to swing which creates a dynamic component.

Many of these issues might not be addressed on the load charts which is why operators need training and routine skills evaluations that address telehandler stability.

If you would like to share your experiences/photos of forklift incidents that can educate others on the principles of safe forklift operation please send them to: bhulberg@D2000safety.com

We will not publish company or individuals names.

Newsletters may or may not open automatically, depending on the web browser settings you are using.