Forklift Data Plate: Not a Bad Idea

When was the last time you looked at the forklift data plate? Is it scratched? Corroded? Missing? While some operators believe their equipment can carry any load that doesn’t lift the rear wheels off the ground, they’re wrong. Operating equipment beyond the limits specified almost guarantees an incident or near miss.

So let’s take a closer look at the data plate and see what we can learn.

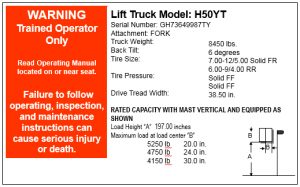

This sample forklift data plate identifies the model (H50YT with a fork attachment). If you use a different attachment that affects the capacity of the truck, a data plate that reflects those changes is required.

Other information listed includes the truck weight, degree of mast back tilt, tire size/pressure, and drive tread width.

Note how the capacity of this forklift is expressed. Since capacity varies based on how you carry the load, the capacity is provided for various distances (measured 20, 24, or 30 inches from the load backrest to the center of the load). For example, if you had 48-inch forks you could safely lift 4,750 lbs. to a height of 197 inches if the center of the weight of your load was at 24 inches.

The difficulty for operators is that not all loads have their weight uniformly distributed around the center of the load. On occasion attachments might be used which move the center of the load farther away from the backrest which decreases the capacity of the forklift.

As a general rule the for every foot that the center of gravity is moved away from the load backrest the capacity of the forklift decreases by about 1,000 lbs.

If you would like to share your experiences/photos of forklift incidents that can educate others on the principles of safe forklift operation please send them to: bhulberg@D2000safety.com

We will not publish company or individuals names.

Newsletters may or may not open automatically, depending on the web browser settings you are using.