Forklift Inicident Investigation

Accidents while operating a forklift require a forklift incident investigation to understand what caused the accident. Consider the following example:

A forklift operator set down a unit of green veneer on some stickers. As the operator started to back out from under the unit the  carriage and forks detached from the front of the forklift (Hyster 90).

carriage and forks detached from the front of the forklift (Hyster 90).

A Forklift Incident Investigation helps determine what happened?

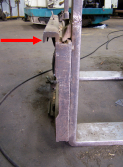

The top of the forklift carriage (photo on left) hooks onto a raised lip and is held in place by the weight of the carriage resting on this lip on the top

The top of the forklift carriage (photo on left) hooks onto a raised lip and is held in place by the weight of the carriage resting on this lip on the top and two brackets on the bottom (photo on right). However, both brackets in this incident were loose. Since the chain was over stretched, when the forks were lowered the heels would strike the ground essentially pushing the carriage up and contributing to the carriage coming off the raised lip.

and two brackets on the bottom (photo on right). However, both brackets in this incident were loose. Since the chain was over stretched, when the forks were lowered the heels would strike the ground essentially pushing the carriage up and contributing to the carriage coming off the raised lip.

Recommendations:

1) Train forklift operators how to inspect chains and forks.

2) Replace over stretched chains on forklifts.

3) Secure forklift carriage clamping brackets using Locktite, top lock nuts, flat washer, and grade 8 bolts.

4) Inspect clamping brackets during routine forklift maintenance.

A thorough forklift incident investigation is essential to help identify maintenance problems that need attention. OSHA has a handy guide on incident investigations. Accidents are problems that lead to solutions!

If you would like to share your experiences/photos of forklift incidents that can educate others on the principles of safe forklift operation please send them to: bhulberg@D2000safety.com

We will not publish company or individuals names.

Newsletters may or may not open automatically, depending on the web browser settings you are using.