Carabiners Connectors FAQ

Using the strictest definition of OSHA fall arrest criteria and ANSI 359, carabiners are classified as connectors. Why is this important? Today, with the advancement of industrial rescue teams, we are seeing more of a trend of rope equipment compliance with these important fall arrest standards. Here are a few questions and answers that should be considered when choosing carabiners for your team. In addition, we will also address some best practices for the use of carabiners.

Q: How are carabiners designed to be loaded?

A: Without exception, a carabiner is designed to be loaded on its major axis. Having stated this, the definition of “major axis” will vary based on the shape and design of the carabiner. The axis of the typical “D” shape carabiner is easily visualized as being down the spine of the carabiner. Whereas the major axis of an oval shape carabiner will bisect the center of the carabiner frame but still parallel to the spine. Some devices such as the Petzl ASAP must be used only in conjunction with an oval carabiner that allows for a wider loading of the major axis and minimizes potential binding that would be present if a “D” shape carabiner were to be used. As with all equipment, strict adherence to the manufacturer’s recommendations is a must.

“major axis” will vary based on the shape and design of the carabiner. The axis of the typical “D” shape carabiner is easily visualized as being down the spine of the carabiner. Whereas the major axis of an oval shape carabiner will bisect the center of the carabiner frame but still parallel to the spine. Some devices such as the Petzl ASAP must be used only in conjunction with an oval carabiner that allows for a wider loading of the major axis and minimizes potential binding that would be present if a “D” shape carabiner were to be used. As with all equipment, strict adherence to the manufacturer’s recommendations is a must.

Q: Are rescue carabiners rated for loading the gate (minor axis)?

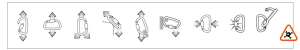

A: Several rescue carabiners do have a minor axis rating as well as an open gate rating stamped on the spine of the carabiner. However, this is done more as a warning of how not to use the carabiner as opposed to condoning dangerous practices. Depending on the make and model, side loading and open gates dangerously weakens the strength of the carabiner. The diagram below was provided by Petzl and it shows several examples of dangerous carabiner applications.

Q: How strong does the gate (minor axis) of a carabiner need to be if the gate is not designed to be side loaded in the first place?

A: It is correct to say that carabiners are not designed to be side loaded, but we all are aware of the realities of life and that bad things can happen unexpectedly. As such, the rescue community builds in some aspect of safety margin into the manufacturing of equipment as well as the rigging of rope rescue systems.

The latest ANSI 359 version now requires a 3,600 minor axis for a fall arrest connector. As of today OSHA doesn’t state a minor axis rating for carabiners. NFPA 1983 requires a 7kN (1574 lbf) minor axis rating for technical use carabiners, and a 11 kN (2473 lbf) for general use carabiners.

A couple of common carabiner examples that D2000 Safety carries are the Mod D Steel Quik Lok with a minor axis rating of 9kN and the Petzl Am’D (Aluminum) with a minor axis rating of 8kN.

As you can see, consensus standards are very diverse on minor axis ratings. What is obvious is that there are substantial safety margins built into all of these high quality rescue products. A good round number for a safety margin promoted by the fire service is somewhere close to a 10:1 for anchorage and connectors. ANSI 359 is the only current consensus standard that states a safety margin specifically for rescue anchorage and that is five times the intended load.

Q: Isn’t 3-stage locking carabiners preferred over 2-stage, and screw-lock carabiners?

A: The term “stage” refers to the number of movements it takes to open a carabiner. 2-stage, and screw type carabiners are still widely used without an abundance of adverse effects. Having said that, the 3-stage versions are almost impossible to open accidently, whereas, on rare occasion, 2-stage versions have been known to open due to rolling contact with a foreign surface such as another rope. Screw type carabiners are fine, but due diligence must be given to the gate so that the closing end is pointing down when in use. This action allows gravity to help keep the gate from unscrewing.

Q: What are the pros and cons when comparing steel carabiners with aluminum carabiners?

A: Types of high quality rescue carabiners currently on the market are vast in numbers. This includes steel and aluminum alike. The obvious difference is their weight. Mountain rescue teams or tower rescuers are much more incline to backpack aluminum carabiners and lighten their load by several pounds.

In terms of the rated strength depending on makes and models the ratings will vary widely. The tensile strength of Steel will run between 36kN (8,100 lbf) to as high as 70 kN (15,750 lbf). Aluminum will typically run between 25kN (5,625 lbf) and 36kN (8,100 lbf). As stated earlier, consider the intended load as well as the rescue environment. Even with a hypothetical large rescue load of 500 lbs,, the lightest rated aluminum rescue type carabiner will still offer you better than a 10:1 safety margin.